Reinforced Earth (RE) Wall is a type of retaining wall that incorporates strategically placed reinforcements within the soil to enhance its strength. The full form of RE Wall is Reinforced Earth Wall.

Table of Contents

Introduction to Reinforced Earth Retaining Wall

In the intricate realm of civil engineering, the Reinforced Earth Retaining Wall (RE Wall) emerges as a sophisticated and meticulously designed solution to address the complex challenges posed by retaining structures. This engineering marvel combines fundamental principles of soil mechanics with innovative reinforcement techniques to provide unparalleled stability and durability. This discourse delves into the comprehensive aspects of Reinforced Earth Retaining Walls, exploring their design principles, construction methodology, key components, and the myriad advantages that make them a cornerstone in modern geotechnical engineering.

Design Principles Reinforced Earth Retaining wall:

Facing the Earth’s Forces

At its essence, the design of a Reinforced Earth Retaining Wall revolves around the fundamental understanding of the forces acting on the wall and the soil it retains. These forces include the lateral earth pressure exerted by the backfill, surcharge loads from adjacent structures or traffic, and potential seismic forces. The wall’s structural elements must effectively counteract these forces, ensuring the long-term stability and safety of the entire system. If you want to know more about the Guidelines for the Design and Construction of RE Walls then see the IRC: SP:102-2014.

Incorporating Reinforcement

A distinctive feature of RE Walls lies in the incorporation of reinforcement elements within the structure. Typically, these reinforcements are metallic strips or grids made of materials like galvanized steel or synthetic fibers. These reinforcements are strategically placed within the soil mass to enhance its tensile strength and mobilize its internal shear resistance. The combination of soil and reinforcement creates a composite material that can withstand significant loads and deformation.

Gravity and MSE Systems

Reinforced Earth Retaining Walls can be broadly classified into two categories: gravity walls and Mechanically Stabilized Earth (MSE) walls. Gravity walls rely on their mass to resist lateral earth pressure, while MSE walls utilize internal reinforcement to impart tensile strength to the soil mass. The choice between these systems depends on factors such as wall height, soil conditions, and the surrounding environment.

RE Wall Construction Methodology:

Site Preparation and Excavation

The construction of a Reinforced Earth Retaining Wall commences with comprehensive site preparation. This involves clearing the area, removing any debris or obstructions, and excavating the foundation to the specified depth. The foundation soil is then thoroughly compacted to ensure a stable base for the wall.

Reinforcement Installation

The strategic placement of reinforcement elements is a critical phase in the construction process. Metallic strips or grids are carefully embedded horizontally within the soil at predetermined intervals. The choice of reinforcement material and its corrosion resistance play pivotal roles in ensuring the long-term effectiveness of the retaining wall.

Backfill Placement

Once the reinforcement is in place, backfill material is carefully deposited and compacted in horizontal layers behind the wall. This backfill material must possess suitable properties to facilitate proper compaction and drainage. The compaction process is meticulously controlled to minimize potential settlement issues and ensure uniform pressure distribution on the wall.

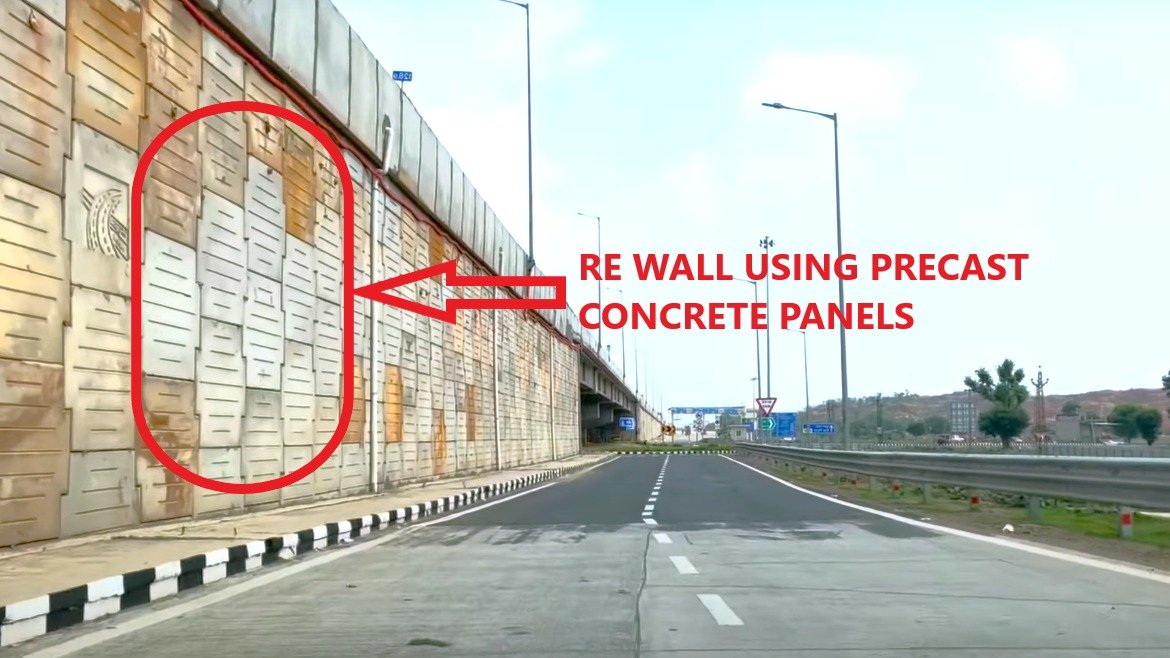

Facing Construction

The facing of a Reinforced Earth Retaining Wall serves both functional and aesthetic purposes. It provides a protective layer to the reinforced soil mass, enhancing its durability and resistance to environmental elements. Facing materials vary and can include precast concrete panels, modular blocks, or even vegetative cover in the case of green walls. The facing elements are anchored to the reinforcement to ensure stability.

Components of Reinforced Earth wall Construction:

Reinforcement Strips or Grids

The heart of a Reinforced Earth Retaining Wall lies in its reinforcement system. Metallic strips or grids, often galvanized for corrosion resistance, form the skeleton that imparts tensile strength to the soil mass. These reinforcements are carefully selected based on factors such as soil characteristics, wall height, and anticipated loads.

Backfill Material

The backfill material serves a dual purpose: providing lateral support to the wall and contributing to the overall stability of the structure. The properties of the backfill, including granular composition, compaction characteristics, and drainage capabilities, are pivotal in ensuring the long-term performance of the retaining wall.

Facing Elements

The facing of a Reinforced Earth Retaining Wall is the visible outer layer that provides protection and aesthetics. Precast concrete panels, modular blocks, or other facing elements are selected based on considerations such as design preferences, structural requirements, and environmental conditions. The facing components also contribute to the overall stability of the structure.

Advantages of Reinforced Earth Wall Construction:

1. Cost-Effectiveness:

RE Walls are often more cost-effective than traditional retaining wall systems due to their efficient use of materials and straightforward construction methodology. The reduced need for extensive foundations and the ability to use locally available backfill materials contribute to cost savings.

2. Versatility:

These retaining walls offer a high degree of versatility, accommodating a wide range of wall heights, soil types, and site conditions. The adaptability of the design makes them suitable for various engineering applications, from highway infrastructure to commercial developments.

3. Durability:

The use of corrosion-resistant reinforcement materials, coupled with proper design and construction practices, enhances the durability of Reinforced Earth Retaining Walls. Their ability to withstand environmental factors contributes to a prolonged service life.

4. Aesthetic Appeal:

The facing elements of RE Walls can be customized to achieve desired aesthetic outcomes. Whether utilizing textured concrete panels or integrating greenery for ecological harmony, these walls can seamlessly blend into the surrounding environment.

5. Eco-Friendly Design:

The use of local backfill materials and the potential for veget.

MoRTH Specification for RE wall Construction

The Ministry of Road Transport and Highways (MoRTH) in India stands as a bastion of regulatory guidance, wielding specific and meticulous specifications for a myriad of engineering structures, among them the formidable Reinforced Earth (RE) Walls. It’s crucial to note that these specifications are not static; rather, they are living documents subject to the perpetual evolution of engineering standards. As such, the vanguard of accuracy lies in consulting the most recent iteration of the MoRTH specifications, ensuring a current compass for the labyrinth of guidelines.

Diving into the intricate tapestry of MoRTH specifications for RE Walls reveals a comprehensive framework, addressing multifaceted dimensions ranging from the design intricacies to the nitty-gritty of construction methodology. Let’s embark on an expedition through the key facets that constitute the fabric of these specifications.

1. Design Criteria:

In the foundational stratum of MoRTH’s specifications lies the bedrock of design criteria. Geotechnical considerations take center stage, demanding an intimate acquaintance with the nuances of soil properties and the load-bearing capacity of the earth beneath. Structural design parameters unfurl like a map, plotting the course through factors such as wall height, surcharge loads, and the seismic dance the structure may encounter. It’s a meticulous ballet of science and engineering. These guidelines extend their reach to the selection of reinforcement materials and facing elements, demanding a discerning eye for materials that can withstand the test of time and pressure.

2. Material Requirements:

A symphony of specifications orchestrates the realm of material requirements. Backfill material, the unsung hero in this saga, is not merely filler but a crucial actor with prescribed qualities and characteristics. Its quality must align with stringent standards to ensure a sturdy foundation for the wall. The reinforcement materials, often the unsung backbone of the structure, are held to standards of corrosion resistance. This is not just about structural integrity; it’s a battle cry against the relentless forces of nature. Facing elements, be they concrete panels or modular blocks, are chosen with a discerning eye, contributing not just to structural stability but also to the aesthetics that harmonize with the environment.

3. Construction Methodology:

As we transition from the blueprint to the ground, the symphony becomes a dance. Guidelines for excavation and site preparation set the stage, demanding a choreography that respects the earth beneath. The installation of reinforcement strips or grids is not a mere technicality but a meticulous art, a strategic placement that defines the sinews of the structure. Backfill placement and compaction, often overlooked but pivotal, demand precision akin to a surgeon’s hand. Recommendations for facing elements shape the facade, marrying form and function in a ballet of construction.

4. Quality Control Measures:

In the theater of construction, the spotlight turns to quality control measures. Soil and material properties undergo scrutiny, a series of tests that form the litmus test for the structure’s robustness. Inspection and testing protocols, akin to rehearsals before a grand performance, ensure that each element aligns with the script. Quality control measures extend their vigilant gaze to the installation of reinforcements and facing components, ensuring that the composition adheres to the symphony envisioned in the design phase.

5. Safety Standards:

The human element takes center stage as safety guidelines unfurl. Ensuring the safety of the workforce becomes not just a legal mandate but a moral imperative. Standards for slope stability, both during the grand performance of construction and the quietude that follows, become the silent guardians against the specter of potential hazards.

In the lexicon of construction, MoRTH specifications for RE Walls are not a mere guidebook; they are the scripture, the compass, and the score that orchestrates the symphony of engineering. Civil engineers, contractors, and all stakeholders are beckoned to this gospel of precision and adherence. It’s not a static doctrine; it’s a living, breathing document that evolves with the science it governs.

For those entwined in the intricate ballet of highway projects, this adherence to MoRTH specifications for RE Walls is not just a regulatory mandate; it’s a covenant with structural integrity and the uncompromising pursuit of excellence. As time unfurls its relentless march, the beacon remains: consult the latest iteration, navigate the labyrinth with diligence, for in precision lies the resilience of the structures that cradle our highways and bear the weight of progress.

Maximum Height of Reinforced Earth wall

The maximum height of a Reinforced Earth (RE) Wall can vary depending on several factors, including the specific design, site conditions, and engineering considerations. In practice, RE Walls have been constructed with heights ranging from a few feet to over 60 feet (approximately 18 meters). However, it’s important to note that the height of an RE Wall is not solely determined by the reinforcement material but is influenced by factors such as:

- Type of Reinforcement: The type and strength of the reinforcement material (typically metallic strips or grids) play a role in determining the wall’s height capacity.

- Soil Conditions: The characteristics of the soil, including its type, cohesion, and internal friction, can affect the stability and load-bearing capacity of the wall.

- Wall Configuration: The specific design of the wall, including factors like the facing material, facing inclination, and the presence of geogrid reinforcements, can influence its maximum height.

- Surcharge Loads: The loads imposed on the wall, such as additional earth or structures above the wall, can impact its stability and height limitations.

- Local Building Codes and Standards: Regulatory requirements and local building codes may impose restrictions on the maximum allowable height for retaining walls, including RE Walls.

SUMMARY

Before designing and constructing an RE Wall, it is crucial to engage qualified geotechnical and structural engineers who can conduct a thorough site analysis, consider relevant factors, and adhere to applicable regulations. This ensures that the wall is structurally sound, stable, and meets safety standards for its intended purpose.

Frequently Asked Questions

What is the use of Geogrid in RE Wall?

The inclusion of geogrid in Reinforced Earth (RE) Walls is a pivotal engineering strategy. Geogrid, a geosynthetic material, is strategically integrated within the soil mass to enhance tensile strength and facilitate interaction with the facing elements. This reinforces the composite structure, providing increased stability against lateral forces. The geogrid acts as a reinforcement matrix, augmenting the overall load-bearing capacity and contributing to the structural integrity of the RE Wall. This engineering approach underscores the meticulous consideration of material properties and geotechnical dynamics in the design and construction of RE Walls, exemplifying a nuanced approach to soil reinforcement.

What are Geocomposites used for?

Geocomposites serve diverse geotechnical functions, notably in soil reinforcement, drainage, and environmental applications. Comprising multiple layers of geosynthetic materials, such as geotextiles, geogrids, and geomembranes, they are engineered for specific purposes. In soil reinforcement, geocomposites enhance the stability of structures like retaining walls. In drainage, they facilitate efficient water flow while preventing soil erosion. Environmental applications include containment systems for waste management. Geocomposites are versatile solutions, combining the unique properties of different geosynthetics to address complex engineering challenges in diverse fields, reflecting their paramount importance in contemporary geotechnical engineering practices.

What is the difference between Geocomposite and Geotextile?

The distinction between geocomposites and geotextiles lies in composition and functionality. Geotextiles are single-layered, permeable fabrics, predominantly serving filtration, separation, and reinforcement functions in geotechnical applications. Geocomposites, on the other hand, are multi-layered structures incorporating various geosynthetic materials, such as geotextiles, geogrids, or geomembranes. They synergistically combine the properties of individual components to address a spectrum of geotechnical challenges, including drainage, reinforcement, and containment. While geotextiles function independently, geocomposites exhibit enhanced versatility, offering tailored solutions for intricate engineering needs, exemplifying the evolving complexity and sophistication in geosynthetic engineering.