Density is figured out with this formula: Density (ρ) = Mass (m) / Volume (V). It’s expressed in kilograms per cubic meter (kg/m³) and shows how much mass is packed into a certain volume. Knowing about density is key when deciding if materials are right for various construction tasks. This article dives into why material density matters, shares Density of Construction Materials as per IS Code (Indian Standard code) and looks at how it plays out in real construction projects.

Table of Contents

The Importance of Understanding the Density of Construction Materials

In construction, understanding the density of materials is crucial for effective project planning and execution. Density, which is the mass per unit volume (usually measured the Density of construction materials in kg/m3), offers important information about material properties that affect structural strength, transportation logistics, and cost calculations. This article explains the typical Density of Construction Materials as per IS Code (Indian Standard code) and discusses their practical impacts in the industry.

Difference between the Density and Unit Weight

Density refers to how much mass is contained in a specific volume of a material, usually density measured in kilograms per cubic meter (kg/m³) or grams per cubic centimeter (g/cm³). It shows how closely the particles of the material are packed together, which influences its strength, stability, and suitability for construction purposes.

Unit weight, which is frequently confused with density, indicates the weight of a substance for each unit of volume and is typically measured in kilonewtons per cubic meter (kN/m³). It reflects the gravitational force acting on the mass of the material within a specific volume. The key distinction is that unit weight incorporates the effects of gravity, making it essential for engineering assessments related to loads and structural stability.

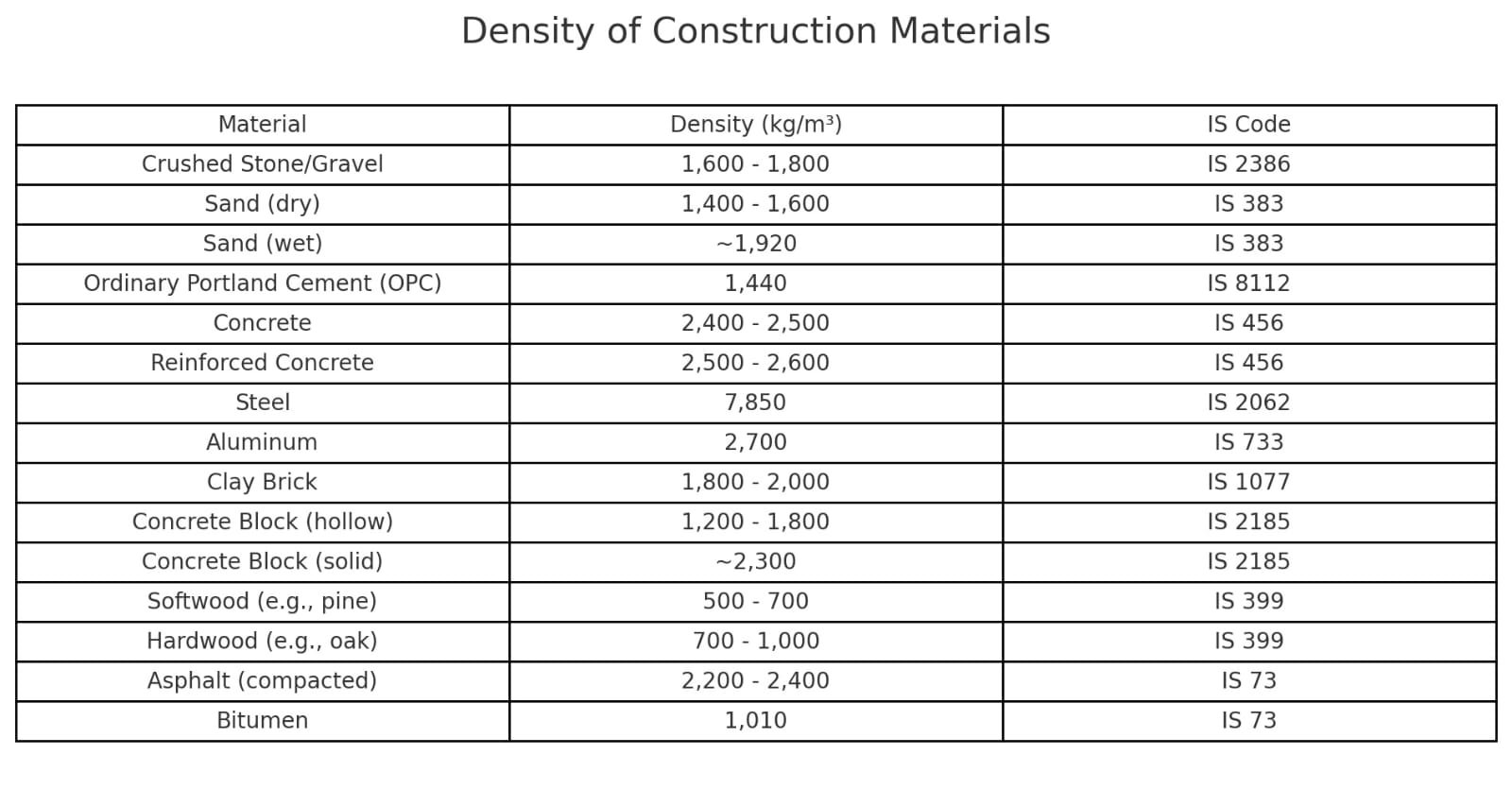

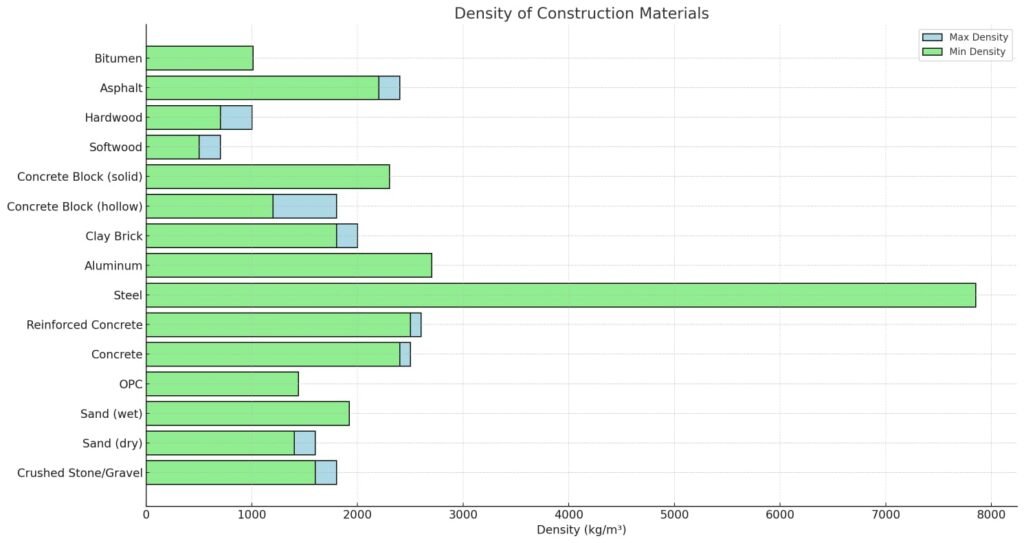

Density of Construction Materials as per IS Code

The Density of Construction Materials is as outlined below:

| Material | Density (kg/m³) | IS Code |

|---|---|---|

| Crushed Stone/Gravel | 1,600 – 1,800 | IS 2386 |

| Sand (dry) | 1,400 – 1,600 | IS 383 |

| Sand (wet) | ~1,920 | IS 383 |

| Ordinary Portland Cement (OPC) | 1,440 | IS 8112 |

| Concrete | 2,400 – 2,500 | IS 456 |

| Reinforced Concrete | 2,500 – 2,600 | IS 456 |

| Steel | 7,850 | IS 2062 |

| Aluminum | 2,700 | IS 733 |

| Clay Brick | 1,800 – 2,000 | IS 1077 |

| Concrete Block (hollow) | 1,200 – 1,800 | IS 2185 |

| Concrete Block (solid) | ~2,300 | IS 2185 |

| Softwood (e.g., pine) | 500 – 700 | IS 399 |

| Hardwood (e.g., oak) | 700 – 1,000 | IS 399 |

| Asphalt (compacted) | 2,200 – 2,400 | IS 73 |

| Bitumen | 1,010 | IS 73 |

| Glass | 2,500 | IS 2835 |

| Lime Mortar | 1,600 – 1,750 | IS 712 |

| Plaster (Gypsum) | 1,440 | IS 2547 |

| Marble | 2,560 – 2,800 | IS 1130 |

| Granite | 2,600 – 2,800 | IS 1124 |

| Timber (seasoned) | 600 – 800 | IS 399 |

| PVC (Polyvinyl Chloride) | 1,380 – 1,400 | IS 10151 |

| Fiberglass | 1,500 – 1,900 | IS 12866 |

| Brick (Fly Ash) | 1,600 – 1,800 | IS 12894 |

| Ceramic Tile | 1,700 – 2,000 | IS 13712 |

| Mortar (Cement) | 2,000 – 2,200 | IS 2250 |

| Fireclay Brick | 1,900 – 2,100 | IS 13703 |

| Insulating Brick | 500 – 700 | IS 2042 |

| Gypsum Board | 600 – 900 | IS 2095 |

| Reinforcement Bar (Rebar) | 7,850 | IS 1786 |

| Polyethylene (PE) | 950 – 1,000 | IS 7328 |

| Lead | 11,300 | IS 405 |

| Copper | 8,960 | IS 191 |

| Zinc | 7,140 | IS 209 |

| Expanded Polystyrene | 10 – 50 | IS 4671 |

| Glass Wool | 12 – 96 | IS 8183 |

| Acrylic | 1,180 | IS 14753 |

| Stone Dust | 1,800 – 2,000 | IS 383 |

| Coal Ash | 540 – 900 | IS 3812 |

| Cement Plaster Board | 800 – 1,000 | IS 2095 |

| Bamboo | 600 – 700 | IS 9096 |

| Cork | 120 – 240 | IS 3512 |

Practical Implications of Density in Construction

Material Selection and Structural Design Understanding the density of materials helps engineers select appropriate substances that meet structural and safety standards. High-density materials are used where maximum strength is required, while lighter materials may be chosen for non-structural elements to reduce the load on a foundation.

Transportation and Handling Densities impact the logistics of transporting materials to the construction site. Heavier materials like steel and reinforced concrete can significantly affect transportation costs and scheduling. Knowledge of material density aids in efficient resource planning.

Cost Estimation and Budgeting Accurate density data allows for better cost estimation, ensuring that projects remain within budget. It helps calculate material quantities more precisely, minimizing waste and optimizing the supply chain.

Conclusion

Density is a fundamental property that influences various aspects of construction projects, from structural design to cost management. Familiarity with the typical densities of common construction materials as per IS codes empowers engineers, architects, and contractors to make informed decisions that align with the project’s needs and budget. For those in the industry, this understanding is crucial to achieving efficient, safe, and economically viable construction outcomes.

Frequently Asked Questions

What is the density of RCC material?

Reinforced Cement Concrete (RCC) usually has a density between 2,500 to 2,600 kg/m³. It is consider both the concrete itself and the steel reinforcement inside it, which adds to the total density. The specific density can change based on the mix design, the kind of aggregates used, and how much steel is included.

What is mass and density in construction?

Mass is the total weight of a material, while density measures mass per unit volume, crucial for selecting construction materials.

What is the density of PCC in kg/m3?

The density of Plain Cement Concrete (PCC) typically ranges from 2,400 to 2,500 kg/m³, depending on the mix and aggregate type.

hat is Density in Construction Materials?