Hume pipe culverts are essential in civil engineering. They play a key role in effective drainage systems, helping to efficiently remove stormwater, wastewater and other runoff. Hume pipe culverts are essential in civil engineering. These cylindrical concrete structures or Hume pipe was created back in 1910 when Sir Walter Hume patented a method to make these reinforced concrete pipes. Since then, improvements in technology and building methods have made the manufacturing process even better, leading to pipes that are stronger, more resistant to corrosion, and easier to install.

Table of Contents

Introduction to Hume Pipe Culvert

In India, the Indian Roads Congress (IRC) sets the rules for designing and construction of culverts. These guidelines are essential for ensuring that infrastructure projects, like Hume pipe culverts, are safe, durable, and functional. This article dives into the main rules and specifications for Hume pipe culverts as per the IRC, emphasizing their importance in effective drainage and maintaining road integrity.

What is a Hume Pipe Culvert?

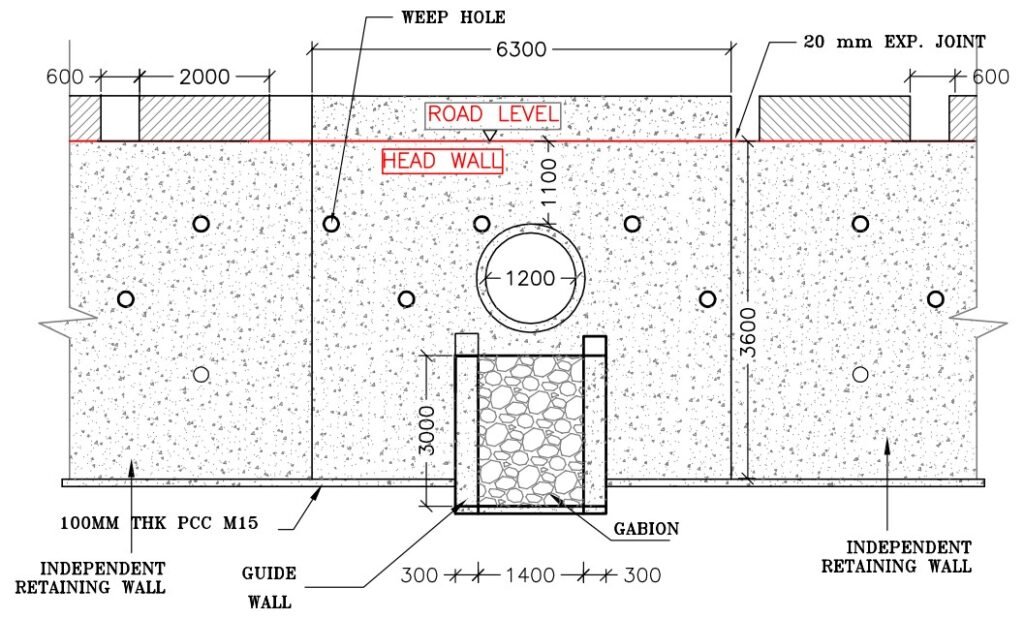

A Hume pipe culvert is a reinforced concrete structure that helps channel water across barriers like roads, railways, or embankments. Named after Walter Hume, these pipes play a vital role in road systems, managing stormwater, irrigation, and drainage. The IRC has established specific guidelines to ensure their consistent quality and performance throughout the country. The Head wall of culvert is enclose by retaining walls.

Design and Manufacturing Process of Hume Pipe

The engineering of Hume pipe culverts is all about the details, focusing on making drainage systems both durable and efficient. These culverts are mainly made from top-notch cement and reinforced steel, which gives them impressive strength and a long lifespan. The reinforcement, typically done with steel cages or mesh, plays a crucial role. It boosts the structural integrity and helps the pipes handle heavy external loads.

When it comes to design, Hume pipes follow strict standards and specifications that are essential for ensuring consistent quality. Guidelines like IS 458 in India and ASTM C76 in the U.S. lay out the necessary requirements for dimensions, strength, and materials. This ensures that every pipe meets a certain performance level, making them dependable for various uses, from city drainage to country roads.

Hume pipes come in different classes and types based on their load-bearing capacity and intended applications. These range from light-duty pipes for smaller drainage tasks to heavy-duty ones that can handle the weight of large vehicles and significant earth cover. Hume pipes are classified into different classes (NP2, NP3, NP4) based on their strength. For example, Class NP2 pipes are suitable for less demanding situations, while Class NP4 pipes are used where more strength is needed.

The manufacturing process for these pipes is carefully managed. It includes steps like mixing cement and aggregates, adding steel reinforcement, and casting the pipes in molds. Quality control is key at every stage, from choosing materials to the final product inspection. Regular tests for compressive strength, water absorption, and permeability ensure that each pipe meets the high standards required for effective drainage systems.

Keeping up with industry standards is crucial for ensuring that Hume pipes are both dependable and long-lasting. The combination of high-quality manufacturing and rigorous quality checks means these culverts can handle the test of time, making them must-haves in today’s infrastructure.

IRC Guidelines for Hume Pipe Culvert

The IRC offers detailed guidelines for the design, construction, and upkeep of Hume pipe culverts, mainly found in IRC: SP 13 – “Guidelines for the Design of Small Bridges and Culverts.” Here are some key points:

Design Considerations

- Load Assessment: The design should consider the maximum load the culvert will support, including vehicle traffic, soil pressure, and possible future traffic increases. The design loads are usually categorized into classes according to IRC: 6 – “Standard Specifications and Code of Practice for Road Bridges.”

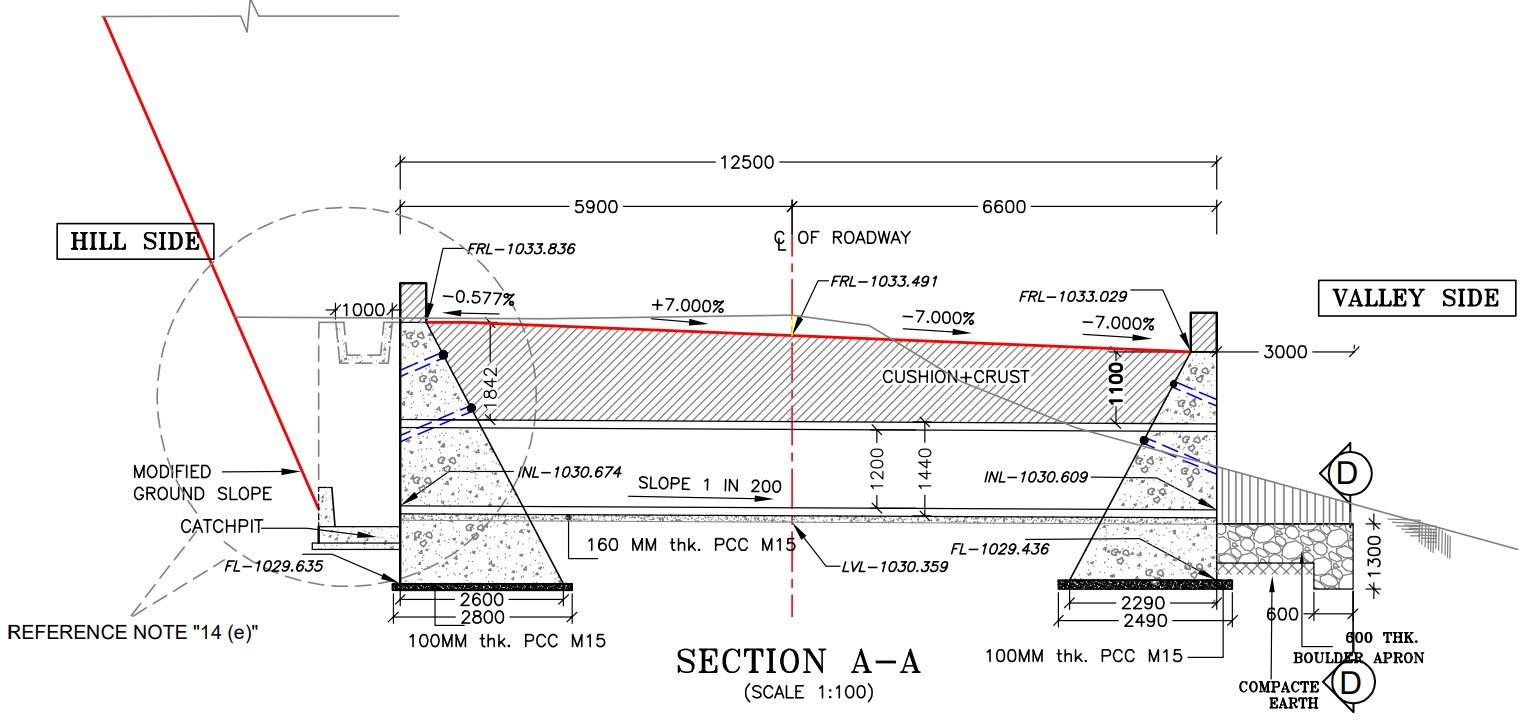

- Hydraulic Design: Proper hydraulic design is essential to ensure the culvert can manage the expected water flow. Factors like maximum discharge, flow velocity, and headwater depth must be taken into account. IRC: SP 13 provides methods for calculating these parameters based on the catchment area and rainfall intensity.

- Pipe Size and Class: The size and class of the Hume pipes are chosen based on what’s needed for both hydraulic and structural purposes. They’re categorized by how much weight they can handle, which depends on how thick the walls are and how strong the concrete is. You can find the standard sizes and classes in IS: 458 – “Precast Concrete Pipes (with and without reinforcement).”

- Minimum Cover: The IRC lays out the minimum cover needed over the culvert to keep the pipes safe from loads on the surface. Generally, you want at least 0.6 meters of cover for Hume pipes that are placed under roads.

Construction Guidelines

- Excavation and Bedding: Getting the excavation and bedding right is key to keeping the culvert strong, ensuring a flat and level base that’s free from rocks and other debris. You should dig the trench deep enough to properly place and align the pipes. It’s a good idea to use a layer of compacted granular material as bedding to create a solid base for the pipes.

- Jointing: Hume pipes are typically connected using spigot and socket joints with rubber rings to make sure they’re watertight. The IRC highlights how crucial it is to have the joints aligned properly to avoid leaks and to keep the culvert durable over time. Positioning the pipes accurately is imperative. Starting at the downstream end, each Hume pipe is placed using suitable lifting equipment to handle their substantial weight.

- Backfilling: Once the pipes are in place, you should backfill the trench with appropriate material in layers, compacting each layer well to prevent settling. The IRC has guidelines on what kind of backfill material to use and how to compact it for stability.

- Headwalls and Wing Walls: Building headwalls and wing walls is a good idea to stop erosion and help direct water flow effectively. These structures also play a role in stabilizing the area around the culvert.

Quality Control and Testing

- Material Quality: The IRC emphasizes that materials should meet IS standards. For Hume pipes, it’s important that the concrete mix, reinforcement, and curing methods align with IS: 458 specifications.

- Inspection and Testing: Keeping an eye on things during and after construction is super important. The IRC suggests conducting tests like pressure tests for joints, load tests for the pipes, and checking the alignment and slope of the culvert.

Maintenance Guidelines

- Routine Inspections: The IRC recommends doing regular checks to spot any issues like cracks, joint shifts, or settling. Catching these problems early means you can fix them before they get worse, which helps the culvert last longer.

- Cleaning and Debris Removal: It’s key to keep the culvert clear of debris and sediment to ensure it works efficiently. The IRC has set out cleaning schedules that should be followed based on the local conditions and how much the culvert is used.

Environmental Factors

- Erosion Control: The IRC emphasizes the need for strategies like riprap, planting vegetation, and proper grading to stop erosion around the culvert, which is crucial for maintaining its strength.

- Flood Management: It’s essential to factor in how the culvert will manage floods, making sure it can cope with heavy flows during severe weather without leading to flooding upstream or downstream.

Applications and Benefits of Hume Pipe Culvert

Hume pipe culverts, crafted from reinforced concrete, are super popular in infrastructure projects because they’re strong, long-lasting, and budget-friendly. They have a bunch of uses across different fields. Here are some main ways Hume pipe culverts are applied:

- Road and Railway Drainage Purpose: Hume pipe culverts are often used to direct water under roads, highways, and train tracks. They help stop water from pooling on the surface, which can cause erosion, flooding, and damage to the infrastructure. Example: You’ll usually find culverts placed under road embankments to let streams or runoff flow through, keeping the road stable and safe for drivers.

- Stormwater Management Purpose: In cities and suburbs, Hume pipe culverts play a key role in managing stormwater. They help move excess rainwater away from roads, buildings, and other areas, lowering the chances of flooding during heavy rains. Example: Urban drainage systems frequently use Hume pipe culverts to link catch basins and storm drains, guiding water to nearby rivers or retention ponds.

- Irrigation and Agricultural Drainage Purpose: In farming areas, Hume pipe culverts are essential for managing irrigation and drainage. They channel irrigation water to fields and help remove excess water, preventing waterlogging that can damage crops. Example: Culverts are often found in canal systems, allowing irrigation water to flow under access roads to fields, ensuring smooth water distribution.

- Culverts in Environmental Conservation Purpose: Hume pipe culverts are also used in conservation efforts to provide safe routes for wildlife under roads and railways, helping maintain ecological connections and reduce wildlife-vehicle accidents. Example: Wildlife crossings often feature Hume pipe culverts, allowing animals to move freely between habitats separated by roads or railways.

- Cross Drainage Structures Purpose: Hume pipe culverts serve as cross drainage solutions where roads or railways intersect with natural water paths like rivers, streams, or valleys. Example: In mountainous regions, these culverts are placed beneath roads to let streams flow freely across the roadway, keeping the road surface intact.

- Industrial and Commercial Applications Purpose: In industrial and commercial settings, Hume pipe culverts help manage water flow around facilities, making sure stormwater or wastewater is effectively diverted away from buildings and work areas. Example: Industrial parks might utilize Hume pipe culverts to manage runoff from expansive parking lots or loading docks, channeling the water to treatment plants or natural bodies of water.

- Sewerage and Drainage Systems Purpose: Hume pipe culverts are used in sewer systems to carry wastewater from residential, commercial, and industrial zones to treatment facilities or disposal locations. Example: City sewer systems frequently rely on reinforced concrete pipes for their main drainage lines, benefiting from their strength and capacity to handle significant water volumes.

- Temporary Access Roads Purpose: Hume pipe culverts are utilized in building temporary access roads over streams or low areas, offering a quick and stable route for vehicles and equipment during construction. Example: Construction sites often set up temporary culverts to let machinery cross over water bodies without harming the environment.

- Flood Control and Mitigation Function: Hume pipe culverts are used in flood management systems to control water flow and lessen the effects of flooding in at-risk areas. Example: These culverts are set up in areas prone to flooding to direct excess water away from important buildings, helping to ease the impact of heavy rains.

- Urban and Rural Infrastructure Development Function: Hume pipe culverts are essential for building both urban and rural infrastructure by offering dependable drainage solutions that support roads, bridges, and other structures. Example: In the countryside, Hume pipe culverts are often installed to let small streams or irrigation channels flow beneath village roads, enhancing access and connectivity.

Conclusion

Hume pipe culverts, built according to IRC standards, play a crucial role in India’s infrastructure by helping manage water flow and ensuring road safety. The strict guidelines from the IRC guarantee that these culverts are durable and can handle different loads and environmental challenges. By following these standards, engineers and contractors help create strong and dependable infrastructure that aids in the country’s progress and development.

Frequently Asked Questions

What is the purpose of Hume pipes?

Hume pipe culverts are vital components in the field of civil engineering. They significantly contribute to the functionality of drainage systems by facilitating the efficient removal of stormwater, wastewater, and various types of runoff.

What is Hume pipes size?

Hume pipe culverts are available in a wide range of diameters, typically starting from 150 mm (6 inches) and going up to 3000 mm (120 inches) or more. Common diameters used in most projects include:

300 mm (12 inches)

450 mm (18 inches)

600 mm (24 inches)

900 mm (36 inches)

1200 mm (48 inches)

1500 mm (60 inches)

1800 mm (72 inches)

2000 mm (80 inches)

What is the minimum cushion for a Hume pipe culvert?

The IRC usually suggests having minimum 600 mm of cushion over Hume pipe culverts placed under roads to shield them from traffic loads. That said, this requirement can change depending on factors like how heavy the traffic is, the size of the pipe, and the type of soil. Sticking to these recommendations is crucial for keeping the culvert strong and lasting a long time.

What is the maximum span of a culvert?

The maximum span of a culvert is typically up to 6 meters.