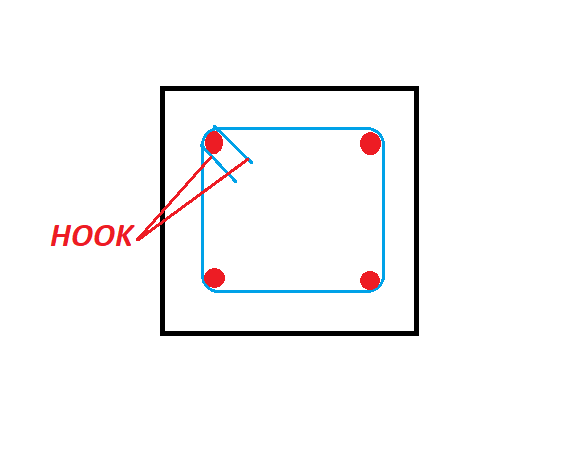

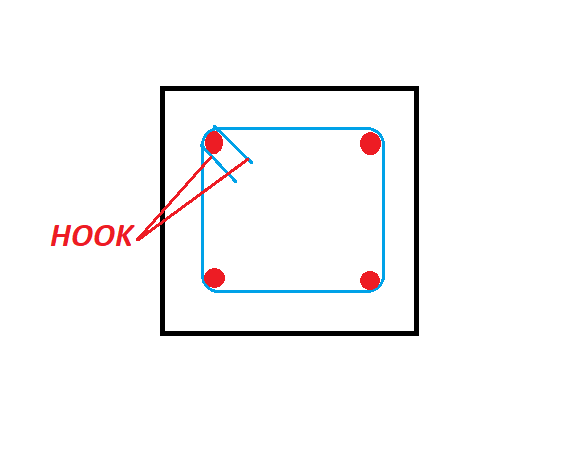

Hook length is the extra length of steel bar provided at the ends of stirrups and reinforcement bars to form a bend (hook). For a stirrup to work effectively, its ends must be bent into hooks of specific angles—typically 45°, 90°, or 135°, as recommended by IS 2502 and IS 456:2000.

Table of Contents

Why Hook Length Is Important in Stirrups

- Stirrups resist shear forces and Hooks ensure the stirrup bar is anchored properly inside the concrete so it does not slip out under load.

- Stirrups keep main longitudinal bars in position.

- To Resist Seismic (Earthquake) Forces.

- Correct hook length ensures these corners remain locked, preventing corner cracks.

Hook Length for Stirrups (90° & 135° Hooks)

For 90° Hook Stirrups

Hook Length (L)

Hook Length = 10d

Where:

d = diameter of the stirrup bar

For 135° Hook Stirrups

Hook Length (L)

Hook Length = 12d

Where:

d = diameter of the stirrup bar

Deduction for Stirrups (45°, 90°, 135° & 180° Hooks)

For 45° Hook Stirrups, Deduction Length = 1d

For 90° Hook Stirrups, Deduction Length = 2d

For 135° Hook Stirrups, Deduction Length = 3d

For 180° Hook Stirrups, Deduction Length = 4d

Example Calculation

Given:

Beam size = 300 × 450 mm

Cover = 25 mm

Bar diameter = 8 mm (stirrups)

Hook = 135°

Effective stirrup size:

L=300−2(25)=250mm, B=450−2(25)=400 mm

Perimeter:

2(250+400)=1300 mm

Hook Length (135°):

Hook Length =2nos. of hook x 12d =2x12x8 =192 mm

Deduction for Hook (135°):

Deduction Length = 2nos. of hook x 2d = 2*2*8 = 32 mm

Total Stirrup Length:

1300+192-32=1460 mm=1.46 m

Conclusion

Hook length formula ensures proper anchorage of stirrups, improving shear resistance, preventing bar slip, and maintaining structural safety as per IS codes.