A pier cap is a structural part of a bridge that sits on top of the vertical supports, called piers. It helps distribute the weight of the bridge deck evenly across the piers, so that the bridge remains stable and is not damaged by excessive stress in one place. The pier cap in Bridge Construction also holds the girders in place. By reducing the stress on the piers, it helps the bridge last longer.

Table of Contents

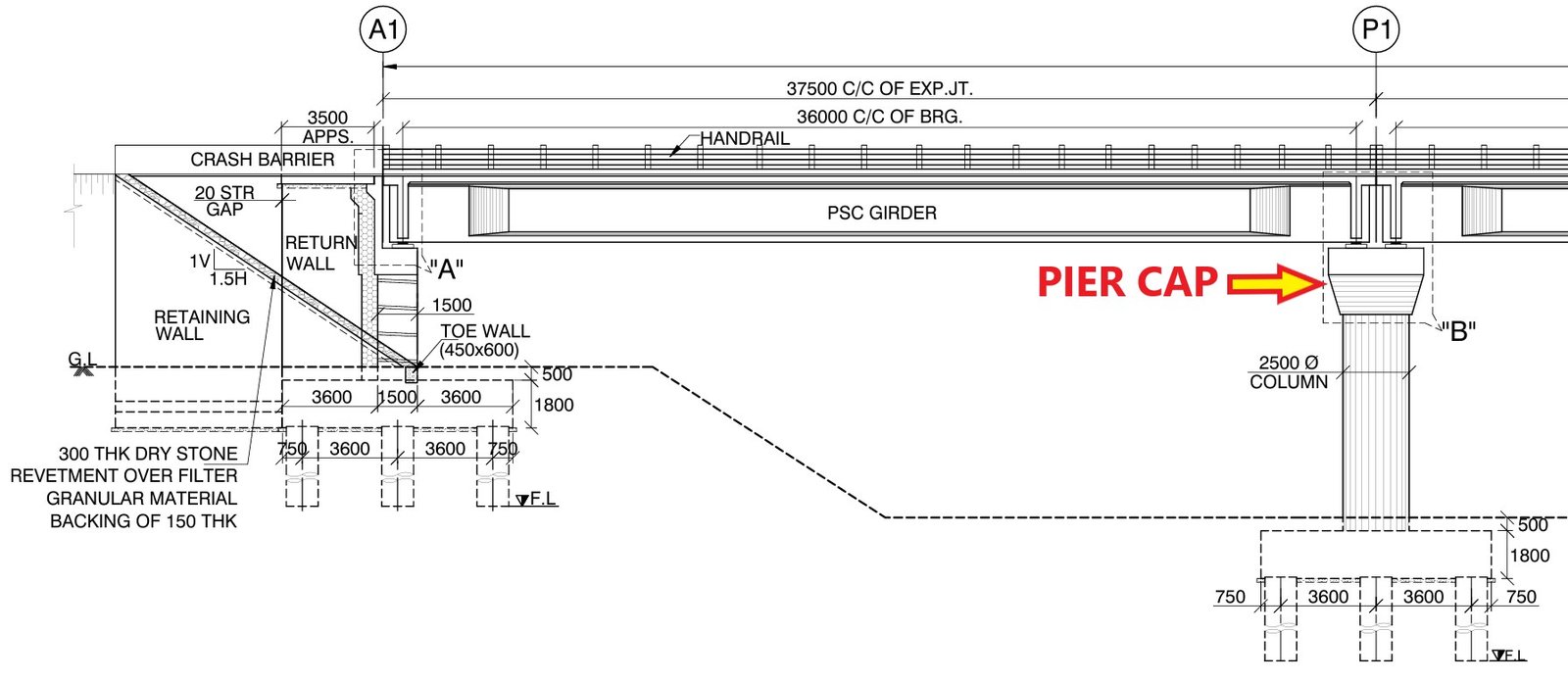

What is a Pier Cap?

A pier cap is an important component of a bridge, positioned on top of the piers, which are the vertical supports of the bridge. Think of the pier cap as a solid platform that helps to spread the weight of the bridge deck evenly across all the piers. By doing this, it prevents too much pressure from being focused on a single point, helping to keep the bridge stable and secure.

What is the purpose of a pier cap?

Pier caps serve several purpose, including:

Supporting Weight:

The pier top is required to sustain the weight of the bridge deck (the component on which vehicles move) and distribute it equally over the piers (the vertical supports). Without the Pier Cap in Bridge Construction, the weight would concentrate in one spot, perhaps causing damage or instability. By spreading the load, the pier top keeps the bridge robust and balanced.

Providing Stability:

The Pier Cap in bridge construction is critical to the bridge’s stability, even under high traffic. Whether automobiles, trucks, or buses pass over, the pier cap keeps the bridge level and does not shift or tilt. This is critical to the structure’s long-term safety and integrity.

Holding Girders in Place:

The huge beams or girders supporting the bridge deck sit directly on the pier cap. This makes the pier cap an essential component of the support system. It offers a firm foundation, ensuring that the girders remain securely in place and the bridge structure holds together properly.

Reducing Stress:

The pier cap helps spread out the pressure that the bridge deck places on the piers. Without it, the piers would take on all the load, leading to more stress and potential wear. By easing that pressure, the pier cap helps the piers last longer and keeps the bridge in good condition for years.

Improving Looks:

Besides its structural function, the pier cap also contributes to the bridge’s appearance. It creates a smooth, uniform connection between the piers, giving the bridge a clean, cohesive look. This aesthetic finish helps the bridge look more intentional and well-designed.

Key Design Factors

When designing a pier cap, engineers consider:

- Load Capacity: It must support both the bridge’s weight and external forces like traffic and wind.

- Material Choice: Most are made from reinforced concrete, but some use steel for added strength.

- Size and Shape: The dimensions depend on how many beams it will support and how wide the bridge is.

- Reinforcement: Steel bars are placed inside to handle pressure and bending forces.

- Environmental Factors: In areas prone to earthquakes or strong winds, special designs are used for extra safety.

How is a Pier Cap Built in Bridge Construction?

Building a pier cap involves several steps:

Setting Up the Shuttering of Pier Cap in bridge construction:

The first step to constructing a pier top is to set up the shuttering, which is a temporary mold for shaping the concrete. These molds are usually formed of wood, steel, or plastic and carefully placed onto the piers. The shuttering ensures that the concrete gets have the correct form and size for the pier cap. The process is important since mistakes in the mold can result in an incorrectly shaped or sized pier cap, affecting the bridge’s overall structure.

Adding Reinforcement:

Once the shuttering is in place, the next step is to add reinforcement. This typically involves laying out steel bars (rebar) according to the specific design and strength requirements of the pier cap. The reinforcement is strategically placed to provide additional strength and support, as concrete alone is strong in compression but weak in tension. The steel bars help prevent cracking and improve the overall durability of the pier cap. The arrangement of these bars is determined by engineers based on the expected load and environmental factors.

Pouring Concrete:

After the reinforcement has been applied, high-strength concrete is put into the shuttering. The concrete is carefully poured to avoid air gaps and fill the whole mold, and use the vibrator machine. The concrete is then evenly dispersed to cover the entire space, ensuring that it fills all sides.

Curing Pier Cap in bridge construction:

Once the concrete is poured, it needs to go through a process called curing. Curing is the process of keeping the concrete moist and at the right temperature for a period of time to allow it to harden properly. Proper curing is critical because it helps the concrete achieve its full strength and prevents it from cracking or becoming weak. During this time, the concrete may be kept covered with plastic sheets or wetted periodically to ensure it doesn’t dry out too quickly. Curing typically lasts for several days or even weeks, depending on the size of the pier cap and the environmental conditions.

Finishing and Inspection of Pier Cap in bridge construction:

Once the concrete has set and hardened, the last phase involves finishing touches and a thorough inspection. Engineers take a close look at the pier cap to spot any flaws like cracks, air pockets, or rough spots. If they find any problems, they’ll fix them up with the right adjustments or repairs. The surface of the pier cap might also get a nice smooth finish or treatment to make it look good or to ensure it bonds well with other parts of the bridge. After the inspection is done and the pier cap checks all the boxes, it’s good to go for the bridge construction.

Different Types of Pier Cap in Bridge Construction

- Rectangular Pier Cap: A simple, common shape used in many bridges.

- Tapered Pier Cap: Uses less material and has a stylish appearance.

- Hammerhead Pier Cap: Has a wider top to support bigger decks.

- Integral Pier Cap: Built as one solid piece with the pier for extra durability.

Conclusion

Pier Cap in bridge construction, playing a key role in strength, stability, and safety. A well-designed pier cap ensures the bridge can handle traffic, weather, and time without problems. Thanks to modern engineering, today’s pier caps are stronger and more efficient, making our roads and bridges safer for everyone.