Counterfort retaining walls are specifically designed to withstand the pressure of soil or other materials in areas with significant elevation changes. Unlike gravity or cantilever walls, counterfort retaining walls feature vertical braces called counterforts. These counterforts are attached at regular intervals along the backside of the wall, serving as tension members to resist lateral earth pressures. Discover how this outstanding design improves the strength and reinforcement of the wall, which makes it suitable for huge projects. In this post, we will take a look at the core concepts of design, building methods and real-world applications for counterfort retaining walls.

Table of Contents

What is Counterfort Retaining Walls:

Counterfort retaining walls are engineered structures designed to resist the lateral pressure from retained soil or other materials. These walls have vertical concrete webs known as counterforts spaced strategically along the wall’s length. The counterforts are linked to both the base slab and wall stem, enhancing the overall support and stability of the structure.

The formation of counterfort retaining walls aims to improve stability and provide uniform weight distribution along the structure. By adding counterforts, these walls effectively reduce bending moments and shear stresses, resulting in a more efficient and cost-effective design than traditional retaining walls. This efficiency is accomplished through the connection of the wall to the base slab, enabling lateral loads to be transferred directly to the foundation. As a result, the risk of wall overturning or sliding is significantly reduced.

Counterfort Retaining Walls Design Considerations:

When designing counterfort retaining walls, key factors to consider include material selection, such as high-quality concrete and reinforcement steel, to meet specific strength requirements. Compliance with relevant standards is crucial for durability and structural integrity.

Site Evaluation: Prior to commencing construction, engineers conduct a thorough assessment of the site where the retaining wall will be erected. Factors such as soil composition, water table levels, and seismic activity are carefully scrutinized. This preliminary analysis aids in determining the environmental challenges that the wall will encounter.

Load Calculation: Subsequently, engineers engage in precise calculations to ascertain the amount of weight that the wall must withstand. Factors like soil density, pressures from nearby structures and hydrostatic forces in heavy rain are considered. This is important for figuring out what the wall needs.

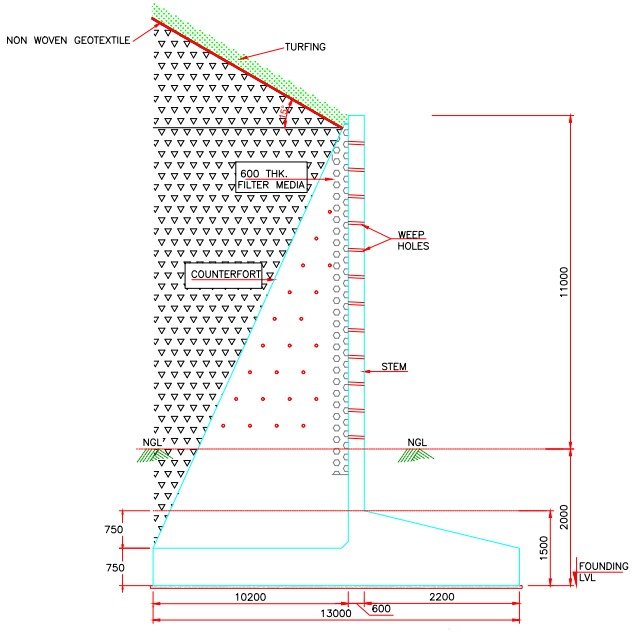

Optimizing the Design: Similar to drafting architectural blueprints, engineers meticulously plan the dimensions and configuration of the wall. Parameters such as height, width, and slope are meticulously defined. Moreover, the strategic placement of counterforts, which provide essential reinforcement, is carefully strategized to enhance stability.

Integration of Counterforts: Counterforts play a pivotal role in fortifying the retaining wall against external pressures. Engineers strategically position these supportive elements and determine their optimal height to effectively counteract the soil forces exerted on the wall. Achieving equilibrium between the wall and counterforts is essential for structural integrity.

Reinforcement Implementation: Engineers strengthen the wall by adding reinforcement bars to the concrete components. This helps the wall withstand external forces and prevents it from collapsing. The steel rods added to the wall make it more resistant to cracking or breaking.

Water Management: Preventing water accumulation behind the wall is imperative to avoid water damage. Engineers proactively plan for drainage solutions by incorporating perforations or pipes to facilitate water runoff. This preventive measure safeguards the structural integrity of the retaining wall and prevents water-related issues in the surrounding area.

Counterfort Retaining Walls Reinforcement Details

Let’s explore the reinforcement details of counterfort retaining walls, focusing on how engineers strengthen these structures to withstand the pressures exerted by retained soil or other materials:

Purpose of Reinforcement:

Reinforcement is essential in counterfort retaining walls to improve their tensile and shear strength. While concrete offers great compression strength, it is weaker when facing tension or lateral forces. Reinforcement helps to address these weaknesses, ensuring the overall stability and durability of the wall.

Types of Reinforcement:

Different types of reinforcement are commonly used in counterfort retaining walls, such as:

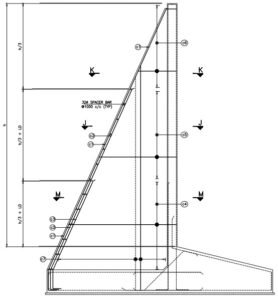

1. Steel Bars: Steel bars, also known as rebar, are commonly used for reinforcement in construction. They are placed both horizontally and vertically in walls to help withstand tension and shear forces.

2. Wire Mesh: Wire mesh can be utilized as extra reinforcement in certain cases, particularly in thinner parts of the wall or in regions experiencing significant tensile stresses.

Placement of Reinforcement:

The placement of reinforcement in counterfort retaining walls is carefully planned to ensure optimal strength and stability: –

Wall Stem: Vertical and horizontal reinforcement bars are embedded within the concrete wall stem. Vertical bars provide support against lateral pressure, while horizontal bars help distribute loads evenly and prevent cracking.

Base Slab: Reinforcement bars are placed within the base slab to enhance its structural integrity and prevent settlement or deformation under load.

Counterforts: Steel bars are positioned within the counterforts to reinforce these vertical elements, which are crucial in distributing lateral pressure and supporting the wall stem.

Size and Spacing of Reinforcement:

The size and spacing of reinforcement bars are determined based on engineering calculations and design requirements.

Bar Diameter: The diameter of reinforcement bars is chosen according to the expected loads and structural needs of the retaining wall. Common diameters range from 10mm to 25mm bars.

Spacing: The spacing between reinforcement bars is meticulously calculated to ensure proper coverage and force distribution. Spacing typically varies from a few inches to several feet, depending on the design specifications and wall dimensions.

Concrete Cover:

To safeguard the reinforcement from corrosion and ensure a strong bond with the surrounding concrete, a minimum concrete cover is specified:

Wall Stem and Base Slab: A concrete cover of usually 20mm to 25mm is provided over the reinforcement bars embedded within the wall stem and base slab.

Counterforts: A similar concrete cover is maintained over the reinforcement bars within the counterforts to shield them from environmental exposure.

Construction Practices:

During construction, accurate placement and alignment of reinforcement are crucial to guarantee the structural integrity of the retaining wall:

Placement Accuracy: Reinforcement bars must be precisely placed according to the engineering drawings and specifications to achieve the desired structural performance.

Proper Embedment: To ensure a strong connection between the steel and concrete parts, it is important to deeply embed the rebar in the concrete. This proper embedment is essential for reinforcing counterfort retaining walls, enabling them to withstand the sideways pressure from the soil and maintain stability and durability over a long period of time. By choosing and placing rebar according to engineering design specifications, engineers can build reliable and robust retaining structures that meet the needs of different construction projects.

Key Components and Structure:

Counterfort retaining walls consist of several primary components: the wall stem, base slab, counterforts, and backfill material. The wall stem forms the vertical face, while the base slab provides a stable foundation. Counterforts distribute lateral pressure and enhance load-bearing capacity. Careful spacing and height considerations optimize strength and stability.

Construction Process:

The construction process begins with site preparation, digging, and setting up formwork to shape the wall. Steel bars are added, and concrete is poured to create the stem, base slab, and counterforts. Attention to consolidation and curing ensures desired strength. Drainage provisions prevent water buildup behind the wall.

Advantages and Practical Applications:

Counterfort retaining walls offer several advantages:

Structural Efficiency: Counterforts enhance load-bearing capacity, allowing for greater heights and lateral support without excessive material usage.

Cost-effectiveness: Despite their robustness, these walls can be economical, particularly in projects requiring significant retaining heights or lateral support.

Aesthetic Versatility: They can be designed with various finishes to blend with the landscape or complement adjacent structures.

Durability: Made from sturdy materials such as reinforced concrete, these walls provide lasting stability with little upkeep needed.

The construction process begins with site preparation, excavation, and the installation of formwork to shape the wall. Subsequently, steel bars are incorporated, and concrete is poured to create the stem, base slab, and counterforts. Counterfort retaining walls are utilized in a range of civil engineering endeavors, from highway embankments to railway constructions, waterfront expansions and commercial projects.

Conclusion:

Counterfort retaining walls provide a reliable solution for stabilizing soil and accommodating elevation changes. With careful design and construction, they offer optimal performance and durability. Their versatility makes them a preferred choice for engineers seeking efficient retaining solutions in infrastructure development.