Constructing a bridge involves a complex engineering process where various elements must work together to ensure stability, durability, and safety. One critical component in this process is the Abutment cap in bridge construction. Often overlooked, abutment caps are crucial for the overall strength of a bridge, providing a solid foundation and effectively distributing loads. This article examines the functions and key considerations for installation of abutment caps in bridge construction.

Table of Contents

What is an Abutment Cap in Bridge?

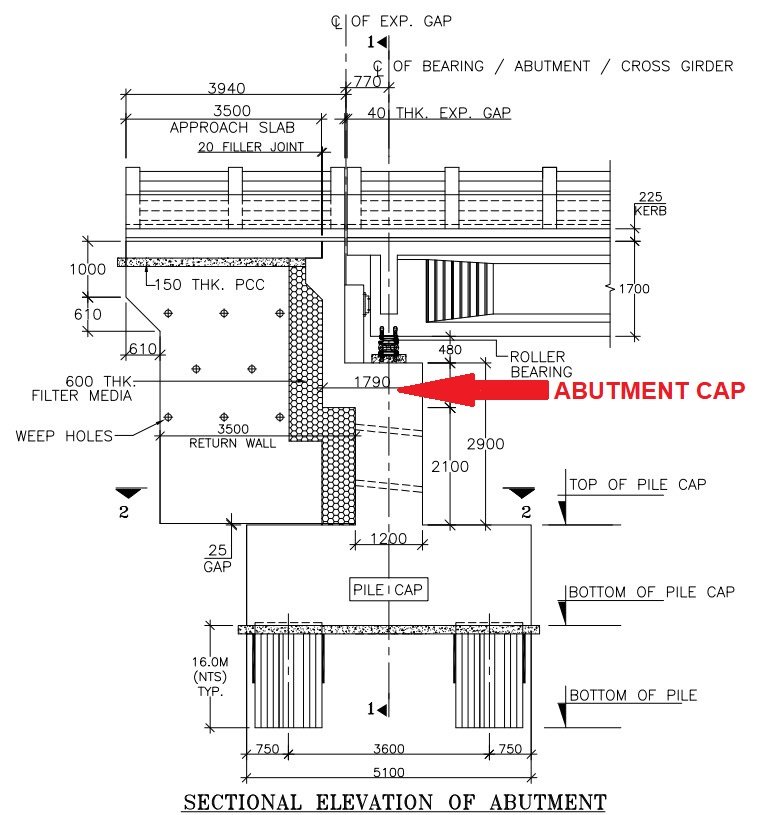

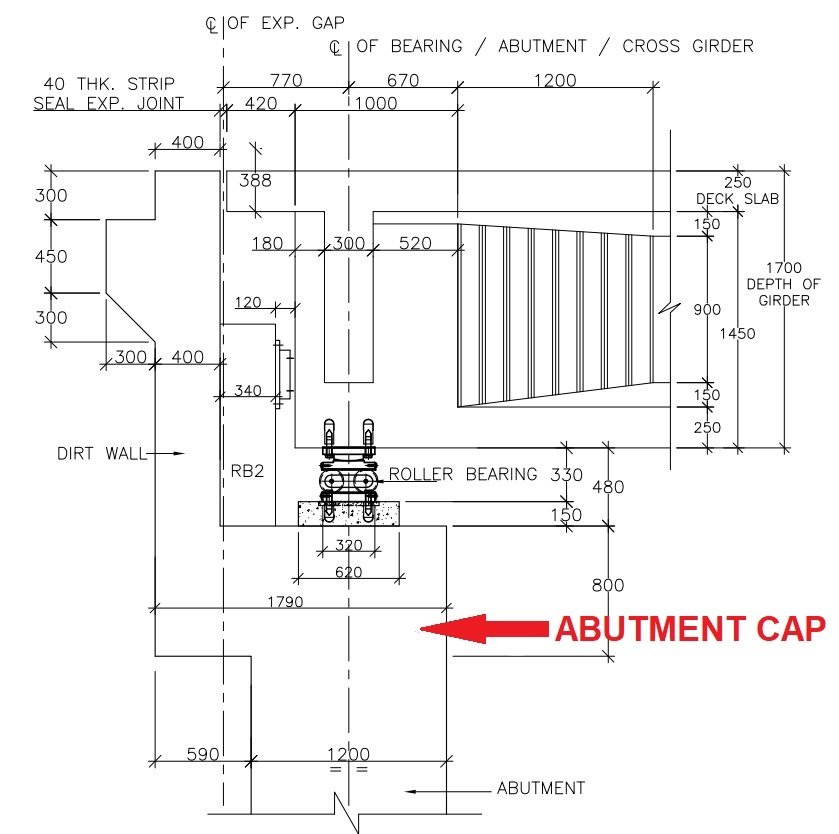

An Abutment cap, also referred to as a bridge seat, serves as the connection point between the beginning and end structures of the bridge. In the bridge or Flyover, one side of the girder is supported by the Abutment cap, while the other side carries the Pile Cap, which rests on the pedestal via bearings, to help distribute loads evenly to keep the bridge stable and safe.

Functions of an Abutment Cap

The Abutment Cap serves several crucial functions in bridge construction. Firstly, it provides a level surface for the girder to rest upon, construct the dirt wall, ensuring proper alignment and stability. Secondly, it helps distribute the weight of the bridge and any traffic loads evenly across the abutments, preventing undue stress and potential structural damage.

Load Distribution:

- Primary Function: The abutment cap helps to evenly spread the weight from the bridge’s superstructure, which includes the deck, vehicles, pedestrians, and other live loads, across the abutments.

- Impact: This distribution helps to avoid concentrated stress and the risk of structural failure, keeping the bridge stable under different loading scenarios.

Structural Support:

- Primary Function: Provides a stable and solid surface for the bridge superstructure to rest on.

- Impact: Maintains the overall stability of the bridge, particularly in areas with varying soil conditions or where differential settlement might occur.

Foundation Integrity:

- Primary Purpose: Improves the strength of the bridge’s base by efficiently spreading out loads.

- Impact: Minimizes the chances of foundation shifting or collapsing, safeguarding the bridge’s stability and safety.

Connection and Transition:

- Primary Function: Acts as a transitional element between the bridge superstructure and the abutments, providing a seamless connection.

- Impact: Ensures efficient load transfer and continuity within the bridge structure, contributing to overall structural coherence.

Alignment and Leveling:

- Primary Function: The main role is to make sure the bridge superstructure is correctly aligned and leveled. The backside of the Abutment is generally constructed as an RE Wall to match the level of approach slab of the bridge with the deck slab.

- Impact: It’s essential for the safe and efficient functioning of the bridge, making sure that vehicles and pedestrians can cross without any problems.

Reduction of Maintenance Needs:

- Primary Function: By providing protection and stability, abutment caps help reduce the need for frequent maintenance and repairs.

- Impact: Reducing long-term maintenance expenses and minimizing inconvenience to bridge users helps improve the overall economic effectiveness of managing bridges.

Key Considerations for Installation

Important Factors to Consider When Installing an Abutment Cap in Bridge Construction

Installing an abutment cap is a vital step in bridge construction that demands careful planning and execution to guarantee the bridge’s stability and durability. Here are the important factors to keep in mind for the installation of an abutment cap:

Material Choice

Concrete: It is often selected for its strong, long-lasting, and versatility in shaping.

Steel: is preferred for its exceptional ability to bear heavy loads and easy installation process.

Design Requirements

Load Capacity: Make sure the design can handle the highest prophesy loads, such as live loads (traffic, pedestrians) and dead loads (self weight of the bridge).

Dimensions and Shape: Ensure that the dimensions and shapes are accurate to properly distribute the load and maintain stability.

Reinforcement: Ensure proper placement of steel bars or mesh within the concrete to enhance strength and resist tension forces.

Site Preparation

Clearing and Leveling: Ensure the area is clear of any debris and leveled correctly to provide a strong foundation for the abutment cap.

Soil Stabilization: If necessary, reinforce the soil to prevent settling and guarantee a robust base. If soil layer weak then we have to provide the pile.

Formwork Setup

Quality of Formwork: Use top-notch, sturdy formwork that can withstand the concrete pour pressure without bending.

Proper Alignment: Make sure the formwork is precisely aligned and leveled to match the design requirements.

Reinforcement Installation

Accurate Placement: Position reinforcement bars or mesh according to the design plans to guarantee the abutment cap’s strength and durability.

Secure Positioning: Fasten the reinforcement to prevent any movement during the concrete pouring process.

Concrete Pouring

Quality Control: Use top-quality concrete with the right mix design to achieve the necessary strength and durability.

Vibration: Compaction of the concrete using vibrators to get rid of air bubbles and ensure effective consolidation around the reinforcement.

Curing Process

Moisture Retention: Keep the concrete moist to help it cure correctly and reach the necessary strength.

Temperature Control: Control the temperature to avoid cracking and ensure consistent strength as the concrete cures.

Formwork Removal

Timing: Only take off the formwork once the concrete has achieved enough strength to bear its own weight and any additional loads.

Careful Removal: Make sure to remove the formwork with care to prevent any damage to the freshly created abutment cap.

Inspection and Quality Assurance

Site Inspection: Make sure to visually inspect for any signs of damage like cracks, gaps, or misalignments.

Testing: Perform strength tests, such as compressive strength tests, to confirm that the concrete meets the necessary standards.

Rectifications: Address and fix any defects or problems found during inspection to guarantee that the abutment cap meets all quality and safety requirements.

Integration with Superstructure

Proper Alignment: Ensure the abutment cap is correctly aligned with the bridge superstructure for seamless load transfer.

Connection Details: Please include the specific design details for connecting the abutment cap to the superstructure, like bearing pads or anchor bolts.

Conclusion

In conclusion, the abutment cap is a crucial element in bridge construction, guaranteeing the structural strength and durability of the bridge. Through load distribution and structural support abutment caps serve a variety of functions that are necessary for the secure and effective functioning of bridges. Recognizing these roles emphasizes the significance of meticulous design and construction of abutment caps in bridge engineering.